WIRE/ROD CALIBRATION EQUIPMENT AND LINES

Straight line wire drawing machines SINGLE CAPSTAN INVERTED VERTICAL WIRE DRAWING MACHINE COMBINED WIRE DRAWING MACHINE WIRE / BAR STRAIGHTENING AND CUTTING MACHINE CHAMFERING EQUIPMENT AUTOMATIC WIRE ROD UNCOILER MACHINES WIRE TAKE-UP MACHINES Optional Equipment for Wire/Rod Calibration Lines

Optional Equipment for Wire / Rod Calibration Lines

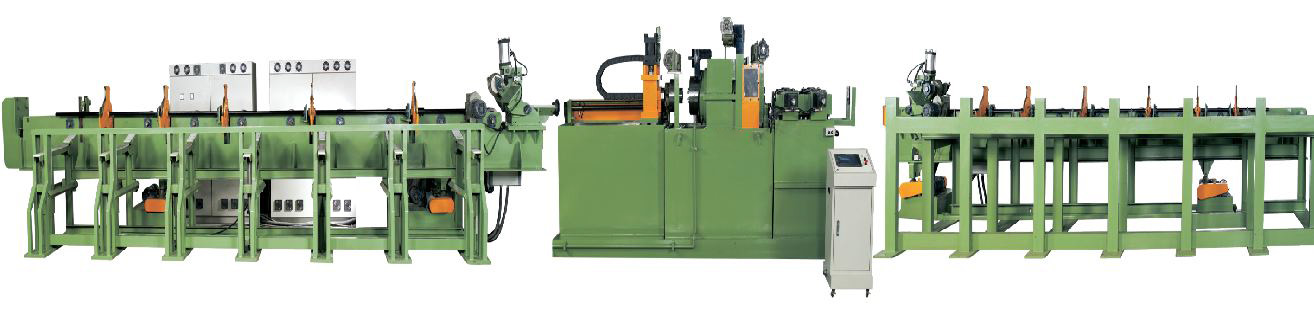

Turning machines for steel surface treatment

Main characteristics of the turning machines for steel surface treatment:

- Turning machines for steel surface treatment are widely used for cleaning oxidized, rusty and uneven surfaces of round steel through hot rolling to obtain a bright surface and precise dimensions.

- Measurement parameters and wear compensation: optical devices control processing, compensate tool wear after the stripping process.

- Safety: a lubricant and coolant ensure smooth and safe operation of the system.

- Waste-free production: the principle of operation of the equipment is based on the automatic sorting of waste for recycling.

- Control system for cleaning the entire production line.

- Effective workflow monitoring.

- Equipment of vibration suppression system.

- Stability of raw material supply.

- Protection of raw materials from damage.

- Working length: 2,5 ~ 8 meters

- Outlet diameter: 20 ~ 125 mm

- Cutting depth: radius 2,5 mm

- Working speed: 10 m/min

- Spindle rotation speed: 200 rpm

The customer can use the equipment in conjunction with two-roll mill leveler as of autonomous action or in conjunction with continuous production line.

Video of the operation of the turning machines for steel surface treatment

AUTOMATIC WELDING MACHINE

Automatic welding machine of horizontal type is fully functional welding equipment, widely used in the production of automobile parts, industrial machine parts and electrical parts. The use of this equipment can reduce the cost, increase product quality and performance.

Features of welding equipment:

- Equipped with a control device, providing reliable welding.

- It supports multiple stationary welding jigs.

- Rotating device can be attached to side clamps.

- Compatible with any type of cutting device.

Welding equipment specifications

| Model | RG-15 | RG-25 | RG-35 | RG-45 | RG-60 | RG-80 | |

|---|---|---|---|---|---|---|---|

| Welding | Diameter of the rod | 3-5 | 6-25 | 6-35 | 8-45 | 10-60 | 19-80 |

| Gas tube assembly | 17.3 | 34 | 48.6 | 60.5 | 76.3 | 101.6 | |

| Material length (turning side) | Ø15x200 | Ø25x300 | Ø35x300 | Ø42x300 | Ø56x300 | Ø76x300 | |

| Working length after installation | 500 | 650 | 800 | 800 | 800 | 1200 | |

| Power | Friction heating kg. | 1200 | 3000 | 5000 | 10000 | 15000 | 30000 |

| Heading pressure kg. | 1300 | 5000 | 10000 | 20000 | 30000 | 60000 | |

| Main shaft 50 HZ, rev./Min. | 4000 | 2175 | 2175 | 2100 | 1500 | 800 | |

| Welding 60 Hz, rev./Min. | 4900 | 2625 | 2625 | 2100 | 1500 | 800 | |

| The primary turning shaft | Switching system, kg = m | Electromagnetic multi-plate clutch | |||||

| 40 | 40 | 40 | 70 | 100 | 160 | ||

| Braking time, sec. | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | |

| Switching system, kg = m | Electromagnetic multi-plate clutch | ||||||

| 70 | 70 | 70 | 100 | 160 | 160 | ||

| Braking time, sec. | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | |

| Main bearing shaft length | 100 | 102 | 110 | 120 | 160 | 180 | |

| Forward Speed | 6000 | 5000 | 5500 | 5300 | 5500 | 3800 | |

| Slide | Reverse Speed | 10000 | 5300 | 5500 | 5500 | 5500 | 3700 |

| Moving Range | 250 | 280 | 280 | 350 | 330 | 300 | |

| Chuck | Hydraulic collet | - | - | Hydraulic three-throw chuck | |||

| Material Processing | Chuck Options | 2800 | 6000 | 9500 | 9500 | 12000 | 15000 |

| Clamp | Hydraulic horizontal open system | ||||||

| Length | 2100 | 4500 | 9000 | 9900 | 13000 | 15800 | |

| Adjustment | Adjustment Time | 0~999.9 | 0~999.9 | 0~999.9 | 0~999.9 | 0~999.9 | 0~999.9 |

| Main drive shaft | 7.5 | 7.5 | 11 | 15 | 22 | 45 | |

| Engine | Hydraulic | 2.2 | 3.7 | 3.7 | 5.5 | 7.5 | 11 |