WIRE PROCESSING EQUIPMENT

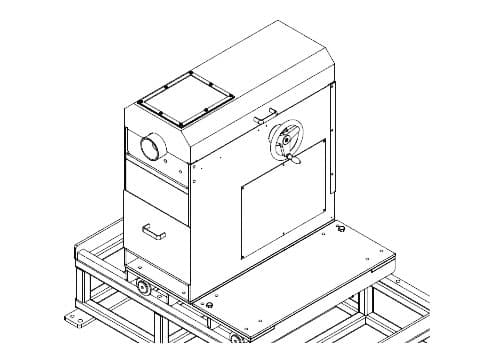

Wire Pointing Machine

To cut the end of the coil / bar by rotating cutting head.

Before the coil enters the drawing die, the beginning of the coil should be reduced the diameter to pass the drawing die. The function of the pointing machine is to reduce the diameter.

- Auto feeding.

- Customized suitable diameter.

- Cutting with four knives.

- Movable-the bottom with tracks.

- Chip collecting device moves to the operating side, which needs to install wheels at the bottom.

- Pointing length: max. 300 mm.

| Working Diameter | Ø19 - Ø80 mm H19 - H63.5 mm S19 - S40 mm |

| Working Bar Length | 2 - 8 M |

| Length Tolerance | <0.8 mm |

| Pointing Length | 400 mm |

| Cutting Depth (Radius) | 2.0 mm |

| Diameter Tolerance | <2 mm |

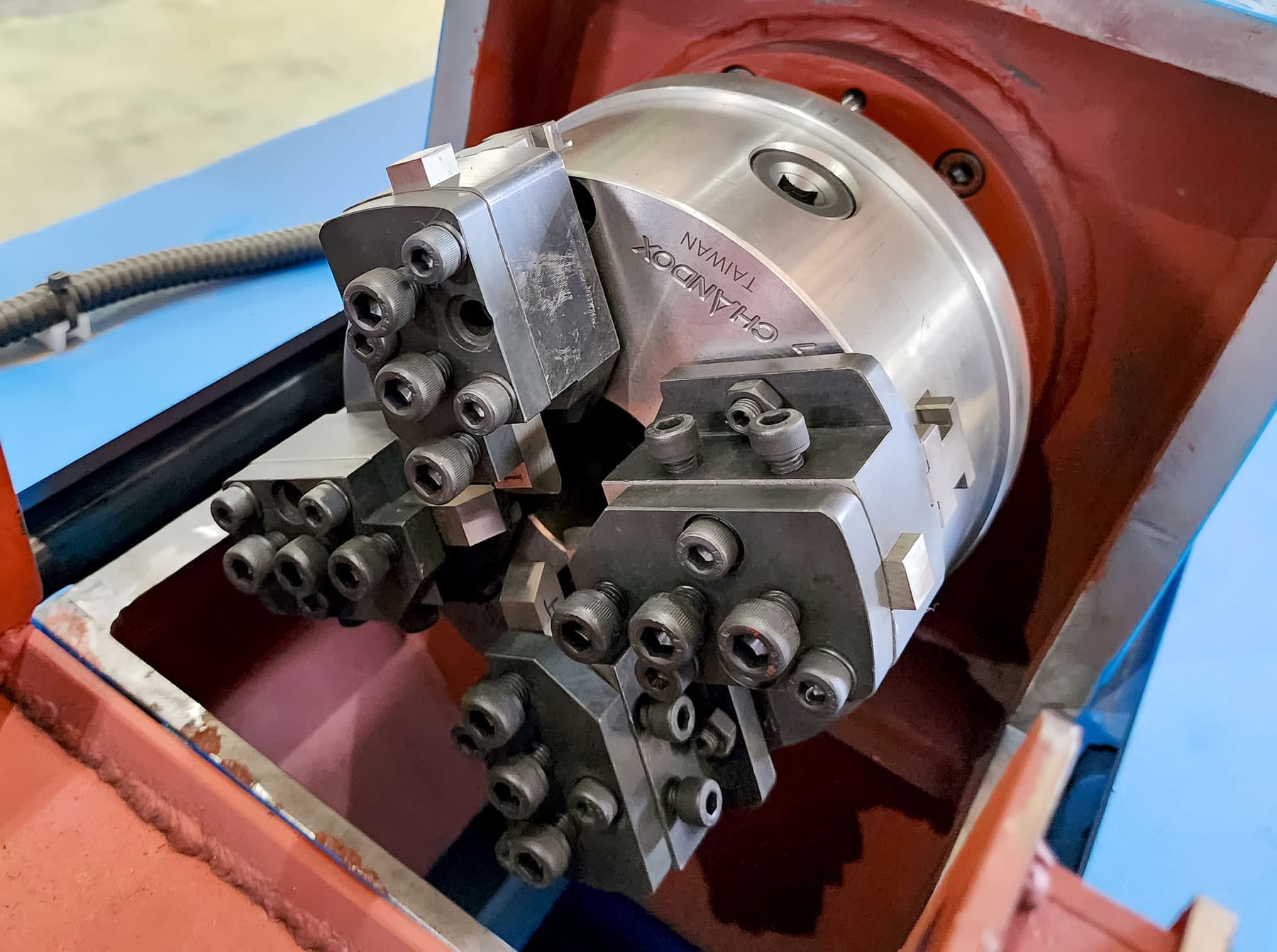

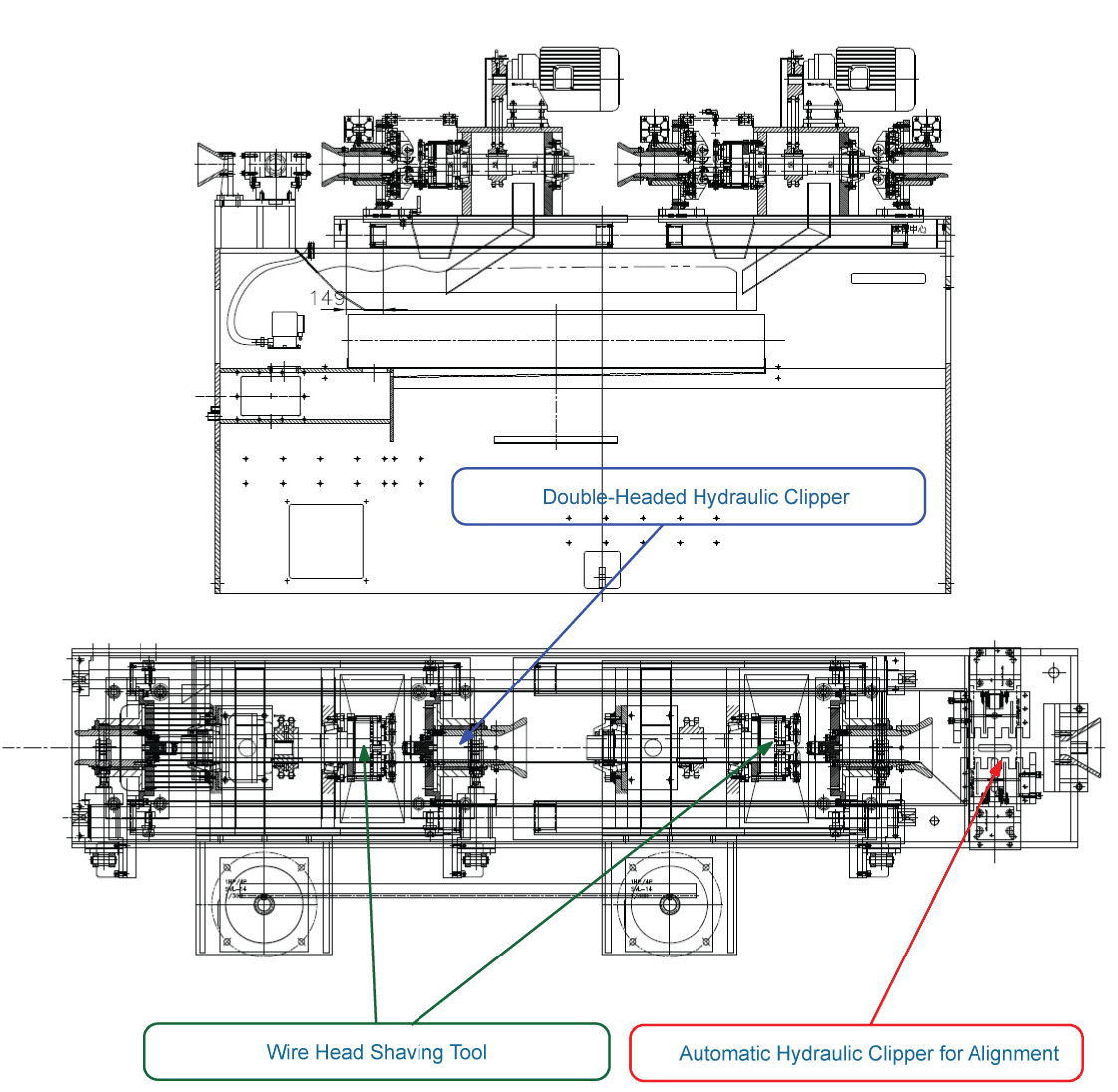

Automatic Wire Shaving Machine RGV series

After straightening the wire rod in the straightening unit of the RGO decoiler, proceed to feed the wire to the RGV shaving machine. Shaving machine will fixate the wire before shaving work can begin.

Shaving work is fully automated, and once the shaving is complete, the machine will come to a stop, and the shaved wire end can be reversed out of the RGV equipment. RGV shaving machine will then slide out of the production line, semi-automatically via railing.

The wire rod is fed further into the drawing die. The wire shaving equipment can work in the same line of equipment synchronously with the drawing machine.

| Model | RGV-20 | RGV-30 | RGV-36 | RGV-45 |

|---|---|---|---|---|

| Wire Range | Ø22 mm ~ 9 mm | Ø32 mm ~ 10 mm | Ø36 mm ~ 25 mm | Ø45 mm ~ 37 mm |

| Power Source | AC 380 V / 50 Hz / 3 Phase | |||

| Shaving Machine Motors | 3 HP + 1 HP Motor with Inverter Drive | |||

| Lubricating Motor | 1/2 HP | |||

| Hydraulic Pump | 5 HP | |||

Wire Shaving Device Features

- Fast shave time: 1.0m length takes about 5~10 mins (shaving time is dependent on wire diameter).

- Produces an uniform round head for smooth insertion through the die, all the way to the automated hydraulic clipper.

- Digital Control: relative to the wire diameter and shaving depth the control system will automatically adjust the rotational and feeding speed.

- The uniquely designed turning tool adopts a reducer motor that drives the speed of the tool and feeding blade.

- Left & right side each has 1 set of hydraulic cylinder for centering. This greatly helps optimize the shaving speed and the roundness of the wire head.

- Pre-requisite process before wire shaving treatment: wire rod needs to be straightened before shaving treatment (straightened length must be longer than the shaving distance).

Wire Shaving Device includes

- Segmented cross clamping device for fixed wire.

- 1 set of 3 pcs guide wheel - clamping device - on the front and rear side of turning tool.

- Lubricating motor: 1/2 HP

- Hydraulic pump: 5 HP

- Wire will be treated within specification of the drawing range.

- Four blades to adjust simultaneously.

- Hydraulic system to automatically move blades during wire head treatment.

- Hydraulic trolley: 1 set (shavings waste collector).

RGV-20 Wire Shaving Device Design

Roller type wire sharpening machines

A wire sharpening machine is an electromechanical intermittent device designed to sharpen the ends of small wire rod. The pointing operation is necessary so that the rod / wire, the diameter of which initially exceeds the diameter of the installed die, enters the drawing bench without difficulty.

The working elements of the roller cutting device are two rotating rollers that directly narrow the end of the wire rod / wire. The rotation of the rolls occurs at a constant speed, and the rolls themselves have furrows with a decreasing step distance.

Roller tipe wire sharpening machines are controlled by a push-button panel. In addition, this pointing machine can also be started with a foot pedal.

Roller type wire sharpening machine RS-3/16S for wire rod sharpening

| Model | RS-3S | RS-6S | RS-8S | RS-16S |

|---|---|---|---|---|

| Wire Range | Ø3.0 - Ø0.8 mm | Ø6.5 - Ø1.5 mm | Ø8.0 - Ø2.0 mm | Ø16.0 - Ø3.0 mm |

| Roller length | 85 mm | 140 mm | 250 mm | |

| Roller diameter | 60 mm | 80 mm | 120 mm | |

| Groove amount | 8 | 10 | 11 | 14 |

| Roller hardness | More than HRC58 | |||

| Roller material | Bearing steel | |||

| Roller rotation speed | 26 rpm | 39 rpm | 32 rpm | |

| Мощность двигателя | 1.5 kW | 5.5 kW | ||

| Wheels for moving the machine | Yes | Optional | ||

| Equipment size (L×W×H) | 600×210×980 | 850×750×1070 | 1000×730×1210 | |

| Weight | 170 kg | 394 kg | 600 kg | |

| Wire rod type | Low-medium-high carbon | |||

Roller type wire sharpening machine RC-7/36 for wire rod sharpening

| Model | RC-7.0-1.6 | RC-13-5 | RC-20-5 | RC-20-10 | RC-20-12 | RC-36-24 |

|---|---|---|---|---|---|---|

| Type | Movable Type | Rotary Type (90° Degrees Rotatable to provide a more rounded pointing) | ||||

| Wire Range | Ø7.0 - Ø1.6 mm | Ø13.0 - Ø5.0 mm | Ø20.0 - Ø5.0 mm | Ø20.0 - Ø10.0 mm | Ø20.0 - Ø12.0 mm | Ø36.0 - Ø24.5 mm |

| Motor Power | 5 HP | 10 HP | 15 HP | |||

| Power Source | AC 380 V / 50 Hz / 3 Phase | |||||

| Control Method | Single Button Operation / Foot Pedal Control | |||||