TOOLS FOR COLD HEADING AND THREAD-ROLLING MACHINES

DRILL POINT DIES FOR SELF-TAPPER DRILLS FORMING

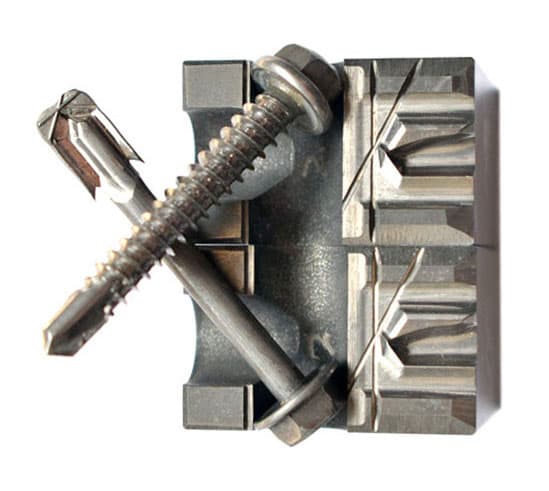

This type of tool is intended mainly for metal screws, but also used for fastening parts from metal profiles, drywall, plastics, chipboard and others, which are divided into several types:

- Pointed black screws that go through the phosphating process

- Galvanized screws

- Hex head screws

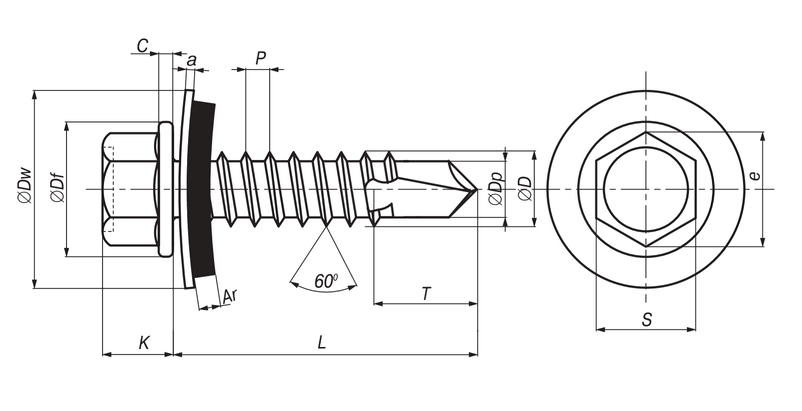

The main parameters of screws with a drill: diameter 2.8 mm - 10 mm, length 9.5 mm - 210 mm

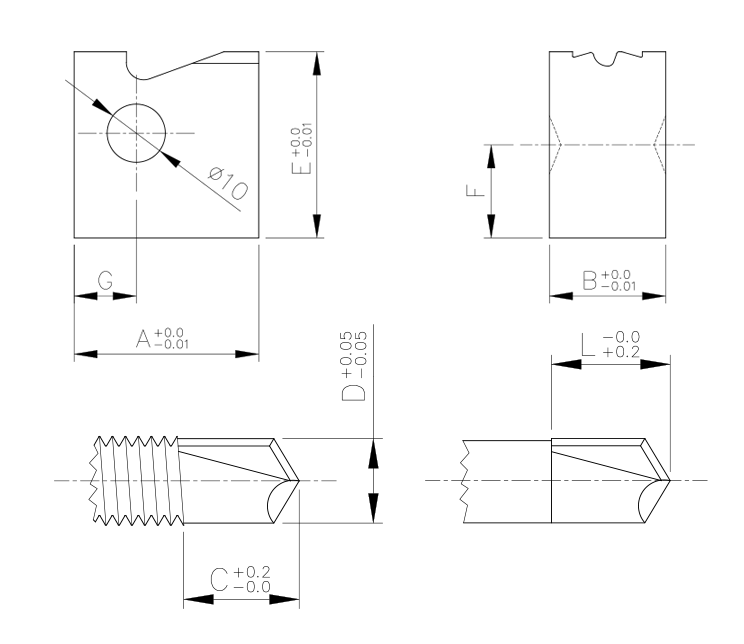

Tool size: 31.75x12.7x25.4 mm; 31.75x20x32 mm or 34 mm; 45x30x32 mm or 34 mm, and also in accordance with the table below or in accordance with the customer’s drawings or on the basis of the finished product provided, indicating the seating positions of the machines, the model of the machines used and the diameter of the wire used as raw material for landing fasteners and hardware.

The formation of the drill occurs due to the compression of the tip of the core of the product.

Type of drill: drill, wolfram wing drill

Material: tungsten carbide, high-speed steel M2, SKH 9 / 51

Coating: PVD (vacuum deposition)

Working parameters of the Drill Point Die

| Tool type | Type 1 | Type 2 | Type 3 |

|---|---|---|---|

| Tool appearance |  |  |  |

| A | 31.75 | 31.75 | 45.00 |

| B | 12.70 | 20.00 | 30.00 |

| E | 25.40 | 32.00 | 32.00 |

| F | 11.4 | 18.0 | 16.0 |

| G | 10.7 | 10.7 | 16.0 |

| Code | Drill diameter | Working length | The length of the drill | Type |

|---|---|---|---|---|

| L1-22 | 2.2 | 2.5 | 1.7 | Type 1 Type 2 |

| L1-23 | 2.3 | |||

| L1-27 | 2.7 | 2.5 3.5 | 2.4 3.2 | |

| L1-28 | 2.8 | |||

| L1-29 | 2.9 | |||

| L1-30 | 3.0 | |||

| L1-31 | 3.1 | |||

| L1-32 | 3.2 | |||

| L1-33 | 3.3 | |||

| L1-34 | 3.4 | |||

| L1-35 | 3.5 | |||

| L1-36 | 3.6 | |||

| L1-37 | 3.7 | 4.2 | 4.0 | |

| L1-38 | 3.8 | |||

| L1-39 | 3.9 | |||

| L1-40 | 4.0 | |||

| L1-41 | 4.1 | |||

| L1-43 | 4.3 | 5.2 | 5.0 | Type 2 |

| L1-45 | 4.5 | |||

| L1-47 | 4.7 | |||

| L1-49 | 4.9 | |||

| L1-51 | 5.1 | 6.4 | 6.2 | |

| L1-53 | 5.3 | |||

| L1-55 | 5.5 | |||

| L1-57 | 5.7 | |||

| L2-22 | 2.2 | 3.2 | 2.2 | Type 1 Type 2 |

| L2-23 | 2.3 | |||

| L2-27 | 2.7 | 3.9 | 3.0 | |

| L2-28 | 2.8 | |||

| L2-29 | 2.9 | |||

| L2-30 | 3.0 | |||

| L2-31 | 3.1 | 4.5 | 3.9 | |

| L2-32 | 3.2 | |||

| L2-33 | 3.3 | |||

| L2-34 | 3.4 | |||

| L2-35 | 3.5 | |||

| L2-36 | 3.6 | |||

| L2-37 | 3.7 | 5.1 | 4.8 | |

| L2-38 | 3.8 | |||

| L2-39 | 3.9 | |||

| L2-40 | 4.0 | |||

| L2-41 | 4.1 | |||

| L2-43 | 4.3 | 6.0 | 5.9 | Type 2 |

| L2-45 | 4.5 | |||

| L2-47 | 4.7 | |||

| L2-49 | 4.9 | |||

| L2-51 | 5.1 | 7.2 | 7.0 | |

| L2-53 | 5.3 | |||

| L2-55 | 5.5 | |||

| L2-57 | 5.7 | |||

| L3-23 | 2.3 | 3.8 | 3.7 | Type 1 Type 2 |

| L3-27 | 2.7 | 4.5 | 3.7 | |

| L3-28 | 2.8 | |||

| L3-29 | 2.9 | |||

| L3-30 | 3.0 | |||

| L3-31 | 3.1 | 5.5 | 4.7 | |

| L3-32 | 3.2 | |||

| L3-33 | 3.3 | |||

| L3-34 | 3.4 | |||

| L3-35 | 3.5 | |||

| L3-36 | 3.6 | |||

| L3-37 | 3.7 | 6.8 | 5.7 | |

| L3-38 | 3.8 | |||

| L3-39 | 3.9 | |||

| L3-40 | 4.0 | |||

| L3-41 | 4.1 | |||

| L3-43 | 4.3 | 8 | 6.7 | Type 2 |

| L3-45 | 4.5 | |||

| L3-47 | 4.7 | |||

| L3-49 | 4.9 | |||

| L3-51 | 5.1 | 9.3 | 8.0 | |

| L3-53 | 5.3 | |||

| L3-55 | 5.5 | |||

| L3-57 | 5.7 | |||

| L4-28 | 2.8 | 5 | 4.5 | Type 1 Type 2 |

| L4-32 | 3.2 | 6 | 5.5 | |

| L4-34 | 3.4 | 7 | 6.2 | |

| L4-39 | 3.9 | 9 | 7.8 | |

| L4-43 | 4.3 | 12.5 | 10.7 | |

| L4-45 | 4.5 | |||

| L4-47 | 4.7 | |||

| L4-49 | 4.9 | |||

| L4-51 | 5.1 | |||

| L4-53 | 5.3 | |||

| L4-55 | 5.5 | |||

| L4-57 | 5.7 | |||

| L5-49 | 4.9 | 15 | 13.7 | Type 1 Type 2 |

| L5-51 | 5.1 | |||

| L5-53 | 5.3 | |||

| L5-55 | 5.5 | |||

| L5-57 | 5.7 | |||

| L6-49 | 4.9 | 17.7 | 16.7 | Type 1 Type 2 |

| L6-51 | 5.1 | |||

| L6-53 | 5.3 | |||

| L6-55 | 5.5 | |||

| L6-57 | 5.7 | |||

Technology

After heading up the head, the semi-finished products to be formed by the drill are loaded into the hopper, which orients the workpieces with the head up, moving them along the guide rulers to the processing zone. There, they are alternately picked up by the rotary mechanism and transferred to the working area, in which the crimping knives are mounted, which, while simultaneously crimping the end of the workpiece, form a drill. The metal flare formed after the compression is further removed during the rolling of the thread onto the self-tapping screw.

Self Drilling Point Forming Dies is used on the following machines: EQUIPMENT FOR DRILLS FORMATION ON SELF-TAPPERS