PACKAGING EQUIPMENT FOR FASTENERS, METAL HARDWARE AND PARTS

Automatic palletizing and stretch wrap system

Today, no large production is complete without systems for stacking containers on pallets and wrapping them in stretch film. Such systems include palletizers and pallet wrappers. Whatever container to pack: bags, rolls, cardboard boxes or packages with plastic bottles, it can be neatly and tightly packed on pallets, and then, if necessary, wrapped with stretch film or put on a film cover.

Technological process of packaging

Orientation of containers on a pallet

Top-sheet stretch wrapping

Horizontal strapping

First stage vertical strapping

Second stage vertical strapping

Auto stretch wrapping

Auto palletizing machine RG-C-893

In order that the finished products in the warehouse do not take up a lot of space and for their proper storage, the products must be neatly stacked and compactly packed. Palletizers are widely used for this purpose. This equipment belongs to warehouse equipment, and is used to create pallets, moreover, consisting of several layers. Products packed on a palletizer take up less space and are reliably protected from external influences and are completely ready for further use and transportation.

Palletizers are extremely useful and productive equipment, as their use eliminates all the mistakes that can be made with manual packaging. The widespread use of palletizers is also due to the fact that nowadays great importance is attached to high-quality packaging of the material, and the supplier must provide the goods in a reliable and compact container, and it is palletizers that perform the main function in the formation of such a level of packaging.

It is the palletizer that forms an absolutely even rectangle from the product, which already in this form is supplied for further packaging.

Palletizer working principle

The formed box is transferred to an automatic pallet forming station (palletizer). Pallets are automatically fed to the station from the store for 5-6 pallets.

The first operation is to turn the box to the required position on the rotary roller table. Further, a separate row is formed from the correctly rotated boxes, which is then shifted onto a pallet using a hydraulic pusher.

When the next layer is set, the pallet moves down to the height of the box, so that the pusher moves the next row of boxes to the previous layer. Cardboard spacers between layers, if necessary, are laid manually by the service personnel.

Next, the finished pallet is transported to an automatic machine for palletizing pallets with stretch film. The pallet is installed on a rotating drive platform, the operator fixes the edge of the film on the pallet and starts the machine from the operator's console.

The formed pallet is pulled by the film with a predetermined tension, overlapping height and the number of layers (revolutions) of the film. After the end of the formation of the pallet, the completed pallet is automatically removed from the loading station area, making room for an empty pallet. The packed pallet is transported to the finished goods warehouse. The pick-up pallet delivery system is synchronized with the empty pallet feeding system.

AUTOMATIC PALLET WRAPPERS

Modern manufacturing enterprises strive to automate the packaging process, reduce the cost of material consumption per unit of product, increase production capacity, and the ability to quickly change the range of goods and services. At the moment, the most advanced way of packing pallets with cargo is packing cargo on a pallet in stretch film.

Pallet wrapper - packaging equipment designed for packing cargo on a pallet in stretch film. The use of a pallet wrapper reduces costs and increases the number of packaged containers. Packing with stretch film will ensure the safety of the goods during transportation and storage, protect against theft, protect the product from mechanical, atmospheric and other influences, simplify its accounting and handling.

Pallet wrappers allow you to achieve the ideal quality of wrapping cargo, even with irregular shapes, and the operating time is reduced to a minimum.

The packaging process using a pallet wrapper is as follows: the operator places the container with the load on the turntable of the pallet wrapper, fixes the stretch film, selects the wrapping program and presses the "Start" button. Further, the packaging process takes place automatically.

The main criterion when choosing a pallet wrapper is productivity, as it is directly related to the type and consumption of the film. The most common is a film with a stretch of 250%, it is optimal in terms of price and quality.

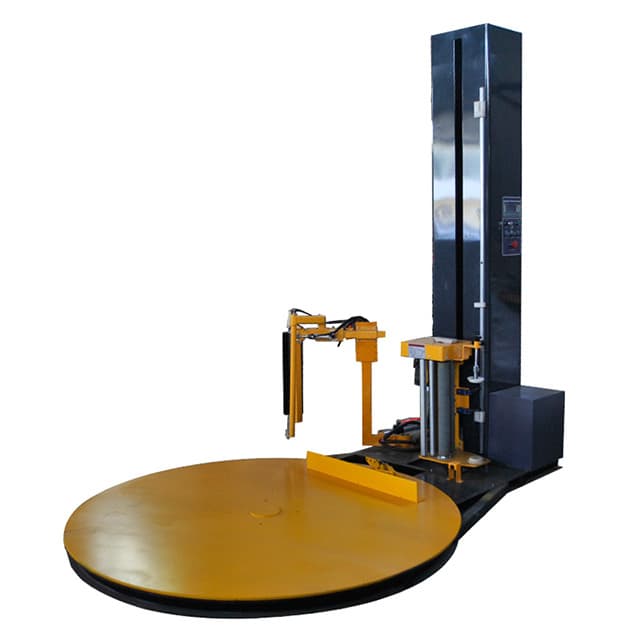

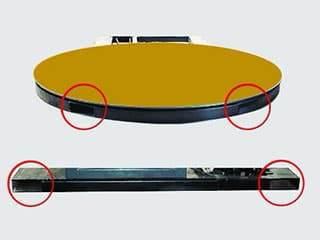

Automatic wrapping machines for wrapping pallets consist of a rotating drive platform and a movable film roll holder. The pallet wrapper has the ability to adjust the tension and height of the film overlay, the number of layers (revolutions) of the film. The rotating platform of the pallet wrapper has a powered roller conveyor for removing the wrapped pallet onto a conveyor for temporary storage of packaged products.

Automatic stretch wrapping machine RG-A-896-R (roller type)

The height can be adjusted in accordance with the requirements of the customer

Automatic stretch wrapping machine RG-A-896-PC (platform type)

Pallet stretch wrapping machine RPT1650FL

Pallet wrapper with pre-stretch film system is a high-tech equipment for wrapping pallets with cargo. The pallet wrapping machine we offer is a profitable, convenient and easy to operate warehouse equipment.

Pallet Wrapping Equipment Design Features

- PLC control.

- Photo-eye auto-height sensing pallet height.

- Separate top, bottom & up-down Wrap Counter options.

- Over-wrap provide more wrap over the top of loads.

- Reinforce wrap times is set to better secure 2 loads placed on top of each other.

- Film Tension Control adjustment on the panel.

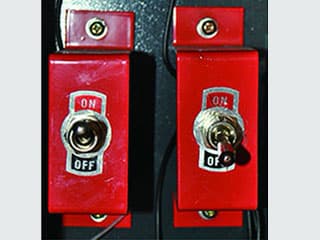

- Separate start, pause and emergency stop buttons.

- Manual carriage up/down.

- Variable Turntable Speed.

- Carriage up/down speed control.

- Manual/automatic exchangeable.

- Powered pre-stretch film carriage, stretch ratio up to 300%, more save the stretch film.

- Carriage door opens for effortless roll change and thread film.

- Film tension adjustable.

Available options

- Ramp.

- Motorised top platen.

- Machine color.

- Turntable diameter: 1800 mm, 2000 mm, 2200 mm

- Weight Capacity: 2500 kgs, 3000 kgs

- Packing height: 2400 mm, 2600 mm, 2800 mm, 3000 mm, 3200 mm

- Button operation or touch screen operation

- With scale / explosion proof type / Counter

Technical specifications of the pallet stretch wrapping machine

| Min load size (L × W × H) | 500 × 500 × 500 mm |

|---|---|

| Max load size (L × W) | 1200 × 1200 mm |

| Max load height | 2000 mm (option: 2400 mm, 2600 mm, 2800 mm, 3000 mm) |

| Max weight capacity | 2000 kgs (option: 2500 kgs, 3000 kgs) |

| Turntable rotation speed | 3-12 rpm (adjustable) |

| Turntable diameter | 1650 mm |

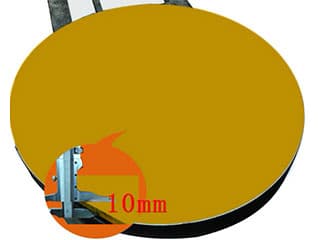

| Turntable height | 85 mm |

| Carriage Up/Down Speed | adjustable |

| Power supply voltage | 220V 1 PH 50Hz |

| Power | 1.55 kW |

| Packing effciency | 20-40 loads/hour |

| Forklifting | Front & Rear |

| Machine size (L × W× H) | 2650 mm × 1650 mm × 2400 mm |

| Machine weight | 650 kg |

| Stretch Film Roll Max. external diameter | 230 mm |

| Stretch Film Roll Internal diameter | 76 mm |

| Stretch Film Roll height | 500 mm |

| Film thickness | 17-35 µm |

Video of the work of the pallet stretch wrapping machine

Automatic clamp and cut type pallet wrapper RPT1650AC

Technical specifications of the pallet wrapper

| Packaged goods | Pallets, Big boxes, Oil drums, big rolls, etc. |

|---|---|

| Min and max load size, (L × W× H) | (200~1200 mm) × (200~1100 mm) × (100~2000 mm) (supply design meet customer require) |

| Max weight capacity | 2000 kgs |

| Machine size, (L × W× H) | 2800 mm × 1800 mm × 2400 mm |

| Shipping Package Size, (L × W× H) | general: 2800 mm × 1800 mm × 850 mm wooden case: 2800 mm × 1750 mm × 950 mm |

| Machine weight | 750 kg |

| Power supply voltage | 220V 1 PH 50Hz (other power supplied) |

| Power | 0.75 kW |

| Packing effciency | 40-50 loads/hour |

| Turntable rotation speed | 3-12 rpm (adjustable) |

| Carriage Up/Down Speed | Adjustable |

Advantages and features of the pallet wrapper

A perfect machine to take the next step in your business, the manual wrapping of your products to the wrapping of your products with a machine. To the "easy to use" where to make the machine is equipped with a display that lets you easily read what the machine.

Supplied with DC motor. Benefit is to protect the motor suddenly stop. The motor could be use more than 5 years.

Button and touchscreen controls are available. The parameter setting on screen. Film tension control, turntable speed and film carriage speed control. Up and down wrap cycles available.

The machine is equipped with an automatic film clamping system at the beginning and trimming at the end of the packaging cycle. The machine automatically loads the film and automatically prunes the film according to the working settings.

Fully automatic conveyor pallet wrapping machine with top sheet dispenser RPT1650CM

Fully automatic pallet wrapper for wrapping pallets with cargo. It is delivered both with the top sheet dispenser and without the top sheet dispenser.

Technical specifications of the pallet wrapping machine

| Packaged goods | Pallets, Big boxes, Oil drums, big rolls, etc. |

|---|---|

| Min and max load size, (L × W× H) | (200~1200 mm) × (200~1100 mm) × (100~2000 mm) (supply design meet customer require) |

| Max weight capacity | 2000 kgs |

| Machine size, (L × W× H) | 2800 mm × 1800 mm × 2400 mm |

| Shipping Package Size, (L × W× H) | general: 2800 mm × 1800 mm × 850 mm wooden case: 2900 mm × 1900 mm × 950 mm |

| Machine weight | 750 kg |

| Power supply voltage | 220V 1 PH 50Hz (other power supplied) |

| Power | 0.75 kW |

| Packing effciency | 40-50 loads/hour |

| Turntable rotation speed | 3-12 rpm (adjustable) |

| Carriage Up/Down Speed | adjustable |

Features of the conveyor pallet wrapping machine

Key Benefits of Using the Pallet Wrapper

- The most secure way to package your load.

- Load may be stacked higher resulting in reduced shipping costs.

- Product can be hidden from view with the use of opaque films.

- Increased protection form the elements, including UV rays.

- Stretch must be cut for product to be extracted.

- Machines use stretch films much more efficiently than if done by hand.

- No operator fatigue as stretch process performed automatically.

- Excellent product presentation.