TOOLS FOR THREAD ROLLING MACHINES

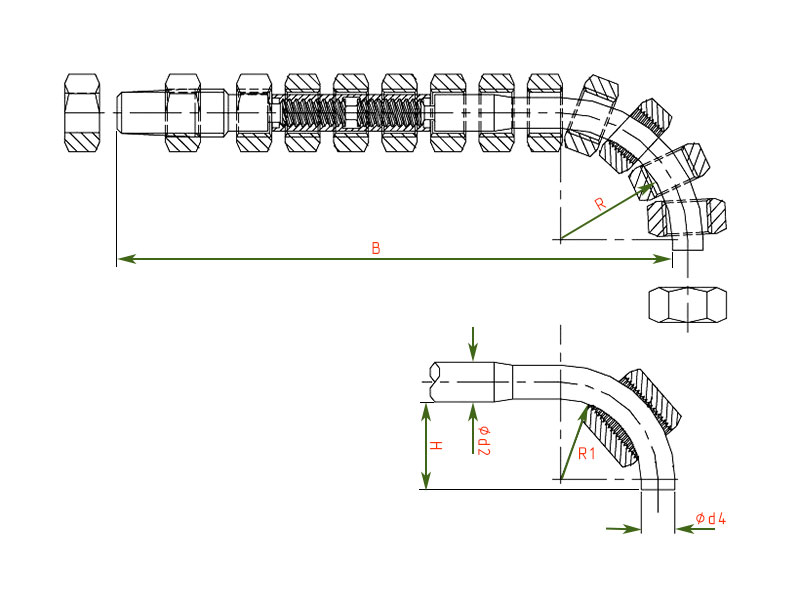

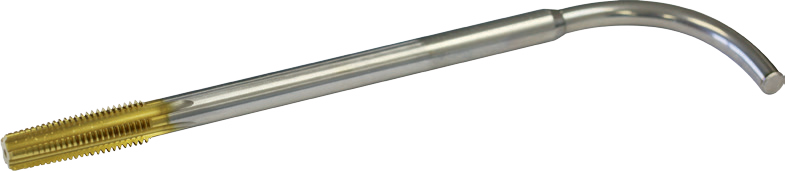

Nut taps with bent shank for carbon steel nuts and cold forged nuts

Purpose of bent shank nut taps

When using automatic tapping machines, the nut being tapped is automatically driven through a bent shank. Therefore, it is possible to make nuts continuously without stopping or reversing the machine. Used on special automatic machines for internal thread tapping in nuts.

Features of nut taps with bent shank

- Due to the long length of nut taps, which makes them difficult to manufacture, especially when grinding threads, they are often made composite: a short cutting and a long tail are made separately, and then they are connected by friction welding, soldering or using a thread.

- Nut Taps with bent shanks are used for threading nuts on automatic machines with a continuous cycle. Blanks of nuts are fed from the hopper into the cutting zone and, after threading, go down the bent shank into the tray.

- Special order item.

- This tap is used on automatic tapping machines.

- The tap will be connected with an short nut tap.

- Bent shank nut taps are manufactured with M2 ~ M30 metric thread, U 2~1-1/4" US thread, 1/8~1-1/4" inch W thread.

- We make design and manufacture of nut taps according to customer requirements.

- These nut taps are made of hidh vanadium high speed steel (HSSE).

- Surface treatment of nut taps: Titanium Nitride (TiN) or Titanium Carbon Nitride (TiCN).

- The nut taps are manufactured with GH accuracy class (13 µm).