EQUIPMENT FOR THE MANUFACTURING OF NAILS

HIGH SPEED THREAD ROLLER SERIES RS-B6-1

Application of screw nails

The presence of thread on a nail causes a much higher joint strength: a screw nail provides fastening four times more durable than a regular construction nail. When mounting, the screw nail enters the material rotating around its own axis. This method prevents damage to the wood fibers and at the same time provides better grip, and hence friction. The strength of fastening here is due to both friction and the shape of the rod.

Screw shank nails are designed for attaching flexible materials such as wood and wood-based panels, as well as structures that bend due to moisture, because they have excellent resistance to bending load. Screw nails are also used in areas such roofing, exterior and interior decoration, packaging manufacture, massive furniture constructions manufacture, screed floor boards, and exterior walls of buildings upholstery. In industrial construction, screw nails are used in the assembly of containers, pallets, crates, and floating equipment.

The process of hammering screw nails is no different from hammering smooth nails. However, the nail moves not only progressively at impact, but is also screwed into the wood without splitting it.

Benefits of screw nails:

- Do not deform the surface of the fastened material, since they are not hammered but screwed in

- Provide high fixing strength - 4 times higher than of an ordinary nail

- Fixing strength does not decrease over time

- Can withstand high dynamic and vibration loads

- Have their own increased strength and resistance to different types of loads

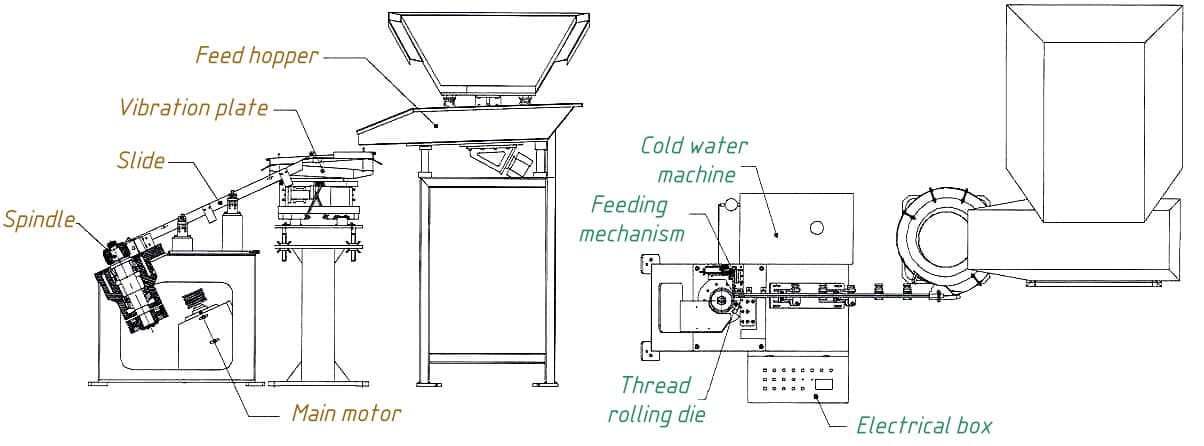

Description of Thread Roller for Nails series RS-B6-1

The machine for the production of screw nails RS-B6-1 is an effective medium-sized stationary automatic electromechanical metalworking machine of continuous action. It is designed for forming thread on pre-prepared blanks in the general manufacturing cycle of screw nails.

Screw nails are usually made from low carbon steel wire, but can be also made from metals such as stainless steel, brass, nickel or aluminum alloys. The steel may also be coated with zinc, cadmium, nickel, chromium or other additional protection coatings.

Thread Roller for screw nail manufacturing RS-B6-1 is made in the form of a floor stand, where an open operating area is formed on the inclined surface.

The main electric motor is equipped with a frequency converter; therefore, the high-speed operation modes are regulated in the stepless mode.

A “snail” type vibratory feeder is installed in the back of the table. The blanks are loaded in bulk into the vibratory feeder, and from there they are individually transformed onto an inclined track by electromagnet. Nails are transformed in such a position that when the thread is applied, it is applied as accurately as possible.

The thread is applied using a rotating matrix wheel (cold rolled) meaning that a centerless cylindrical matrix is used when the screw blank is rolled between two or three round dies to create a finished thread. The stamps are made in accordance with the basic standard parameters of screw threads; their replacement does not require a long time. The operating area is illuminated by an adjustable stem lamp.

Finished product is unloaded through an inclined tray into an assembly container.

Thread Roller RS-B6-1 is controlled by a programmable logic controller (PLC) with a necessary set of functions for tuning to the cycle. Settings are entered using the touch buttons.

Specifications of Thread Roller for screw nails series RS-B6-1

| Wire Rod Diameter | mm | 2.0 - 4.1 |

|---|---|---|

| Nail Length | mm | 30 - 90 |

| Performance | pcs/min | 500 - 1000 |

| Motor power | kW | 3 |

| Vibration tank capacity | kg | 5 |

| Weight of equipment | kg | 1300 |

| Overall Dimensions | mm | 1400 * 1400 * 1600 |

Thread Rolling Equipment Sketch