CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

AUTOMATIC CONTROL PANELS

Control & Measurement Instrumentation Equipment Composition & Features

There are two main control panels for the whole-line of furnace. The one is the temperatures control panel. The other one is the motors & pumps control panel.

| |

| Front washing temperature control | |

| Hardening furnace temperature control | |

| Quenching tank temperature control | |

| Rear washing temperature control | |

| Tempering furnace temperature control | |

Temperature recorder

| |

| Abnormal temperature indicator with alarm system | 1 unit |

| Furnace running layout indicator | 1 unit |

| Cooling fans | 1 unit |

| Voltage meters & ampere meters | 1 unit |

| The gas burners control system as the following attached details |

| |

| Inverter of de-phosphating equipment | 2 sets |

| Inverter of hardening furnace | 1 set |

| Inverter of quenching tank | 1 set |

| Inverter of tempering furnace | 1 set |

| PLC: Mitsubishi Q serious (made in Japan) | 1set |

| Magnetic contactor (TE France) | 1 unit |

| Transformer | 1 set |

| Push button | 1 unit |

| Relay (Japan Omron) | 1 unit |

| Conveyor deviation alarm indicator | 1 unit |

| Abnormal indicator with alarm system | 1 unit |

| Cooling fans | 1 unit |

| Breaker | 1 unit |

| Digital timing display | 1 unit |

| Voltage meters & ampere meters | 1 unit |

The Control and Measurement Instrumentation RG-810C consists of the following components:

- Distribution Cabinet

- Distribution Cabinet Cooling Fan

- Temperature regulator.

- Automatic Temperature Control System (manufactured by RKC Japan).

- The Control Panel with a graphic display with visualization of equipment and function keys (in English)

Temperature Control Panel type RG-810GE (gas)

Temperature Control Panel type RG-810E (electricity)

Automatic Temperature Control Panel type RG-810A (electro) Specification

| 1 | Automatic temperature control controller 0-1200°C (type RKC, Japan) | 3 sets |

|---|---|---|

| 2 | SSR 3 phase 220-440V x 160 KW | control 3 zones |

| 3 | Automatic Alert System | 1 unit |

| 4 | Furnace failure alarm | 1 unit |

| 5 | Voltmeter / Amperemeter | 1 unit |

| 6 | Voltmeter / Amperemeter Mode Switch 220 - 440V, 10A | 1 unit |

| 7 | Recording temperature device (6 points). Made in Japan | 1 set |

| 8 | Signal lamp / auxiliary relay | 1 set |

| 9 | Magnetic contactor | 1 set |

| 10 | Transformer (for cyclic control) | 1 set |

| 11 | Keys with the Backlit | 1 set |

| 12 | Alarm relay | 1 set |

| 13 | Conveyor deviation alarm system | 1 set |

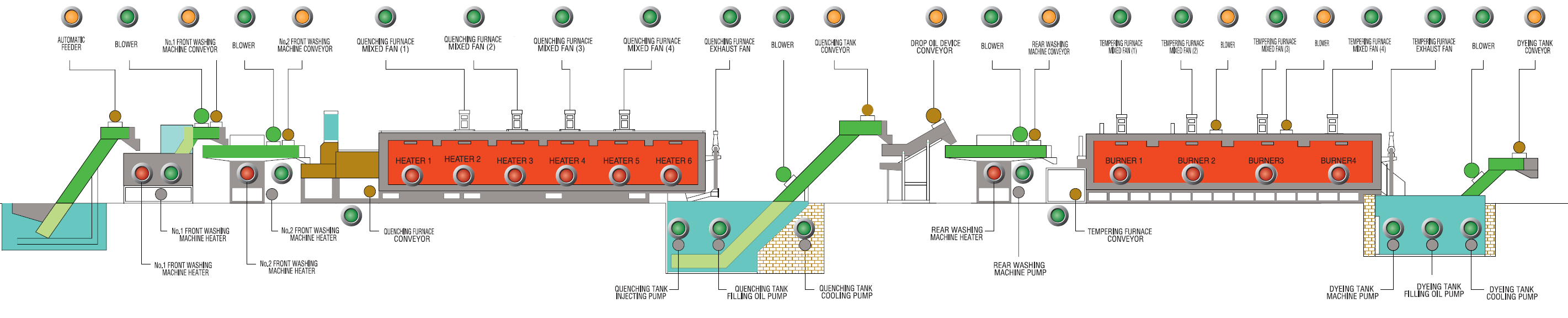

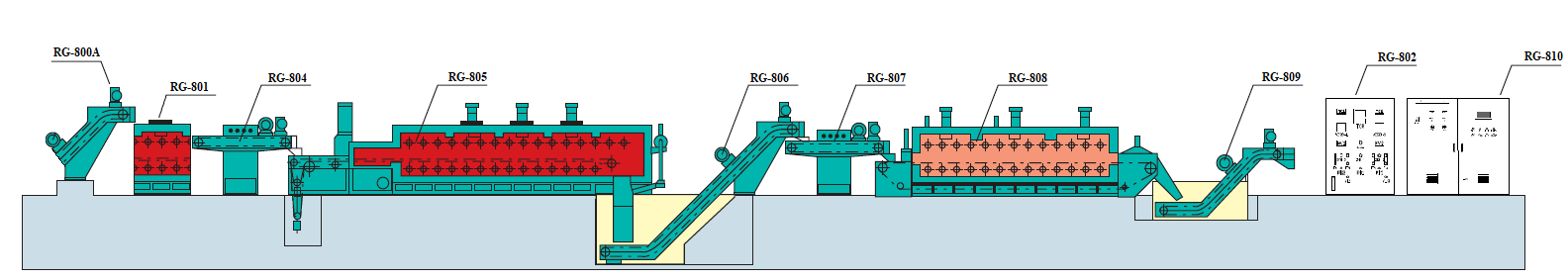

Visualization of equipment (for reference only)