MECHANICAL WIRE DESCALING MACHINE

Mechanical Type Bending & Brushing Descaler RG-SB7

Wire Descaling Machine cleans wire rod from scale mechanically. With this cleaning of the surface from scale, the wire or rod is subjected to periodic kinks in different planes between the rollers, after which the wire goes to the final cleaning with steel brushes. This method of descaling is economically feasible, suitable for surface cleaning, mainly from carbon steel, the dross of which, when bent, is relatively easily destroyed and falls off.

Equipment Features

- Descaling by mechanical bending.

- Mechanical cleaning with brushes.

- Automated control of the steel brushes via PLC control programme to delicately peel off the mill scale layer without damaging the wire rod surface. Function of automatic notification of the replacement of steel brushes.

- This equipment can clean up the mill scale layer of the wire rod and maintain wire cleanliness up to 90%. (A clean wire can greatly help prolong the life of consumable parts such as the drawing die mold and others).

- This equipment can assist and eliminate the need for pre-pickling to save on acid and waste treatment costs.

- Working wire diameter: Ø5.5 mm ~ Ø 7.0 mm (medium carbon steel and low carbon steel). At the request of the Customer, Wire Descaling Machine for cleaning wire with other diameters are supplied.

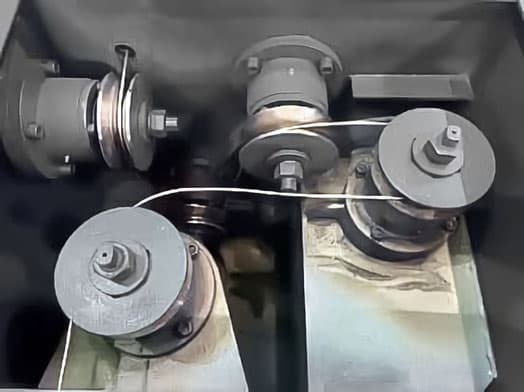

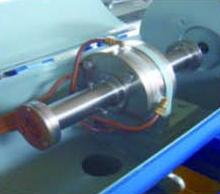

Mechanical cleaning unit with brushes

- Adopts guiding and straightening rollers to provide uniform brushing.

- Drive Power: 12 HP.

- Alloy Steel Brush: 4× Set of Alloy Steel Brushes and Motors.

- Brushing Motor: 3 HP×4.

- Automatic Brushing Adjustment:

- Brushing Motor w/ electromagnetic switch sensor for automatic adjustment via PLC control system.

- HMI Control & Monitoring Station.

- The speed of the brush cleaning unit is synchronized with the speed of the drawing line.

- Direction: to be advised by Customer.

- Alloy steel brushes with a lifetime usage of approx. 3000 tons.

- Power Source: 380V / 50Hz / 3 Phase.

Bending Descaler

- Bending descaling rollers are made of pure tungsten carbide with an average life of approximately 5 years.

- Descaling rollers are aligned horizontally and vertically at distinctive angles and positions to provide the best possible descaling effect.

- Interior of descaling machine is equipped with a mill-scale collection chute to allow funneling of the mill scales into a waste disposal bag.

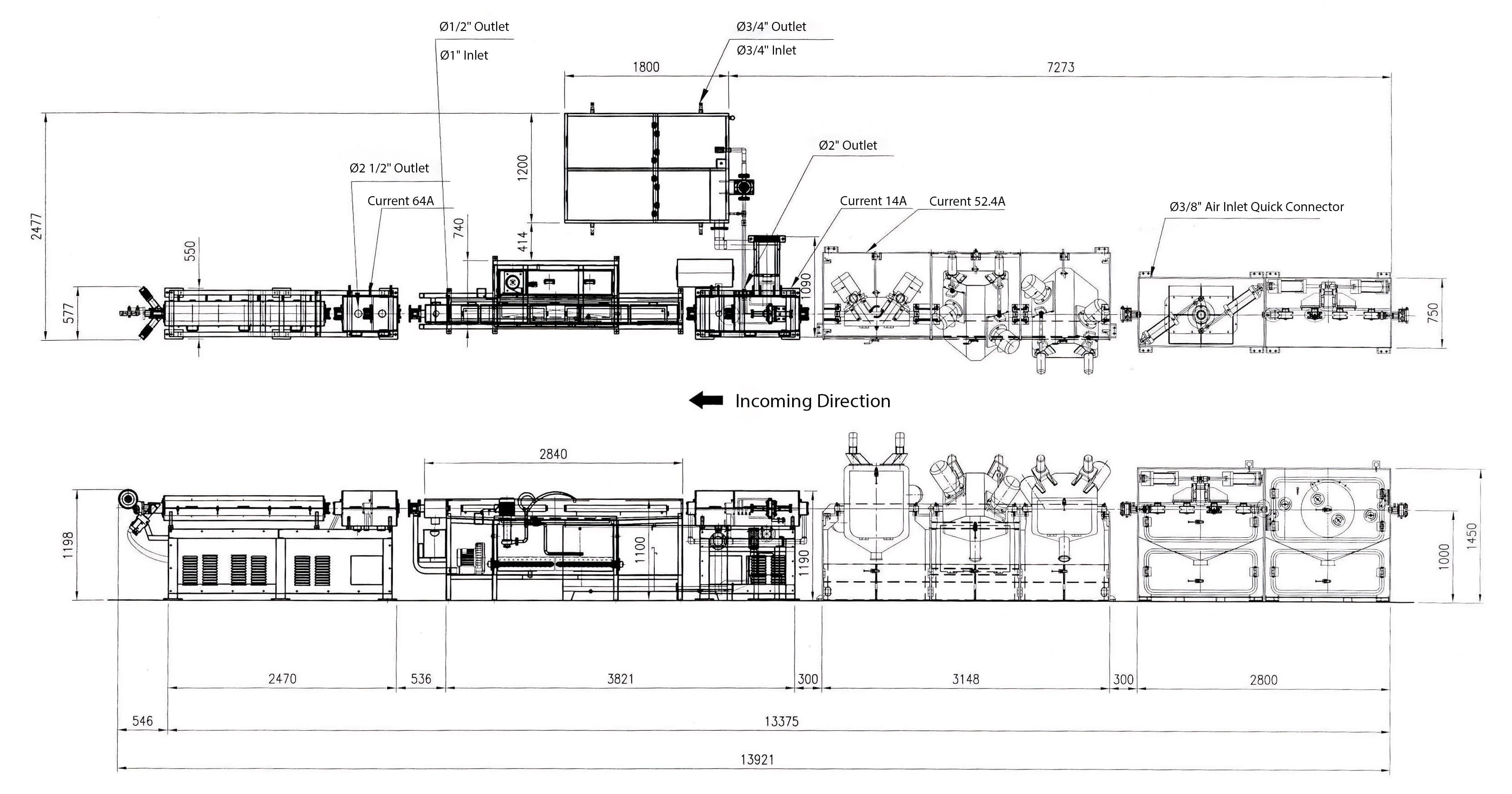

EQUIPMENT FOR MECHANICAL DESCALING, WASHING, APPLYING AN SUB-LUBRICATING COATING AND DRYING

Application Equipment:

The quality of surface preparation depends on the quality of the resulting wire rod wire. For this purpose, the surface of rod mill scale must be removed completely, to create a relief, facilitating capture lubricant provides high-quality wire surface lubricant layer applied as a thin film of lime or borax. Equipment for descaling wire is applied before drawing to reduce friction in the channel between the dies, reducing the effort of drawing, lowering the temperature in the deformation and the magnitude of the residual stress in the wire after drawing.

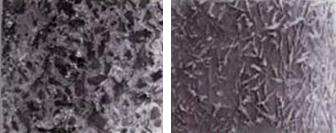

The surface of the wire before and after processing

Characteristics of the equipment:

Equipment for descaling wire is designed for pre-treatment, cleaning and coating of the wire:

- The equipment is suitable for wires of high, medium and low carbon steel.

- It is characterized by minimal emission of waste acid and minimal cost to the process of removing scale (excluding money spent on line etching treatment of exhaust gases, boilers, civil engineering, etc.)

TECHNOLOGICAL FLOW OF DESCALING LINE RS-C SERIES

Rough descaling

with bending rollers

Finishing descaling

with steel brushes

Washing

in water

Applying an

sub-lubricating coating

Hot air

drying

Technical specifications of the equipment RS-C Series

| Descaler |

|

|---|---|

| Flushing system |

|

| Coating |

|

| Drying |

|

| Control panel | The main control panel: consists of a monitor, keyboard, with which you are installing and configuring the parameters of drawing and control units. The main control panel provides access to all functions of the equipment. |

| Supply voltage | At the request of the customer. |

| Operating mode | 24 hours / 3 shifts / 25 days / 80% of effective capacity |