STEEL WIRE ROPE. CORD. CONTROL CABLE. CONDUCTIVE CABLE

GENERAL INFORMATION CALIBRATED WIRE CALIBRATED ROD SHEET METAL EPDM BONDED WASHER STEEL WIRE ROPE WIRE ROPE SLINGS STEEL CONVEYOR BELT

CONTROL ROPE. CONDUCTIVE CABLE

GENERAL PURPOSE CONTROL CABLES

| Product | Design | Construction | Diameter, mm | Normative document | Intended use of product |

| One lay stainless steel ropes type ЛК-О |  | 1х7 (1+6) | 0.30-2.00 | TU 14–173–46–2006 ТУ 14–173–132–2003 | In car alarm systems, mirrors of VAZ new modifications |

| Zinked steel ropes |  | 1х12 | 1.00-1.80 | TU 14-178-429-01 | Used in hand brakes, clutches, accelerators, speedometers, hood opening mechanisms, ovens, etc. |

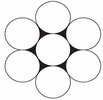

| One lay zinked steel ropes type ТК |  | 1х19 (1+6+12) | 0.80-6.00 | GOST 3063-80 DIN 3053 | Used in cable ways, automobile construction, as wire lines lightning-protection, wire-braced and supporting cables. |

| One lay zinked steel ropes type ТК |  | 1х37(1+6+12+18) | 2.50-6.00 | GOST 3064-80 DIN 3054 | Used in cable ways and cable cranes. |

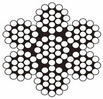

| Two lay zinked stainless steel ropes type ЛК |  | 7х7 | 0.80-6.00 | GOST 3066-80 DIN 3055 | Used in automobiles, computing technics, cable ways, as wire-braced, rigging cables and cables for cargo towage |

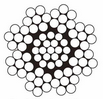

| Zinked stainless steel ropes |  | 7х19 | 1.50-6.00 | GOST 3067 DIN 3060 | In conveyer belts |

| Steel ropes 8x7 + 1x19 |  | 8x7 + 1x19 | 1.50-2.00 | In car window regulators. |

CONDUCTING CABLES

|  |  |

|  |  |

Specification

| Isolation | High-density polyethylene HDPE | Law-density polyethylene LDPE | Polyvinylchlorid PVC | Polypropylene PP | Peat-oil mixture POM | PA6 | Nylon resin |

| Electric conductor | + | + | + | + | |||

| Outer covering | + | + | + | + | + | + |

Technical specifications

| Specification, mm | Outer diameter, mm | Diameter of cable without isolation, mm | Inner diameter, mm | Construction (wire diameter+number) |

| 4.20 5.00 | 4.00-4.20 4.80-5.00 | 3.10-3.30 4.00-4.20 | 1.50-1.70 1.90-2.10 | 0.50×17 0.60×18 /0.50×21 |

| 8.20 9.00 | 8.00-8.20 8.80-9.00 | 6.10-6.30 7.10-7.30 | 2.60-2.80 3.60-3.80 | 0.80×21 0.80×24 |

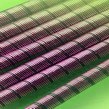

FLEXIBLE ELECTRIC CABLES

| Used for power transmission. Construction: |

Specifications

| Diameter, mm | Diameter tolerance, mm | Layers quantity | Vibration | Max. Positive angle of torsional deformation | Min. Positive breaking tension, N.m | Rough weight, kg/100 m |

| 2.00 | 0.02 | 3 | --- | 150 | 0.60 | 1.80 |

| 2.40 | 3 | 150 | 0.60 | 2.60 | ||

| 3.15 | 4/5 | 2.0 км/ч. | 120 | 0.80 1.00 | 4.60 4.60 | |

| 3.20 | 4 | |||||

| 3.60 | 4 | --- | 100 | 2.00 | 5.80 | |

| 3.70 | 0.05 | 4/5 | 100 | 2.20 | 6.30 | |

| 3.80 | 4/5 | 90 | 2.50 | 6.50 | ||

| 4.00 | 4 | 80 | 2.80 3.00 | 7.20 8.80 | ||

| 4.38 | 5 | |||||

| 4.45 | 5 | 70 | 5.00 5.20 5.20 | 9.10 9.70 10.20 | ||

| 4.60 | 5 | |||||

| 4.70 | 5 | |||||

| 4.80 | 4 | 55 | 5.80 | 10.40 | ||

| 5.00 | 4/5/6 | 50 | 6.30 6.50 | 11.30 12.70 | ||

| 5.25 | 3 | |||||

| 6.00 | 4/5/6 | 45 | 8.50 | 16.60 | ||

| 6.20 | 4/6 | 35 | 10.00 | 17.30 | ||

| 7.90 | 5 | 24 | 12.00 15.00 | 28.70 28.80 | ||

| 8.00 | 4/6 |