WIRE PLATING EQUIPMENT

HOT-DIP ZINC-ALUMINUM WIRE COATING LINE

Difference in protective metal coatings

Zinc (ZN) — is the most common and traditional anti-corrosion metal coating. It is applied by immersing the sheet steel in a zinc melt, or by electroplating it. But the galvanic method (the method of applying the metal coating on the surface by electrolysis) does not give an opportunity to apply a sufficient zinc layer for good corrosion protection.

The higher the zinc content, the thicker its thickness on each side and the higher the corrosion protection.

Galfan (ZA) — zinc alloy containing from 4.5% to 6.2% aluminum. Due to aluminum, the alloy is characterized by higher corrosion resistance than that of a simple zinc coating.

Upon contact with the environment, aluminum oxidizes very quickly, forming an oxide film. The alumina film is chemically stable, does not deteriorate over time, and is an excellent protection for problematic (from the point of view of corrosion) places of the metal sheet: cutting edges and scratches on the coating surface. Due to the presence of aluminum, the development of corrosion under the polymer coating will develop much more slowly, the likelihood of peeling paint from the protective coating is reduced.

Aluzinc (AZ) — a melt containing 55% aluminum, 43.4% zinc, 1.6% silicon. The coating combines the high protective properties of aluminum and the protective properties of zinc. Compared with galvanizing, this type of protective metal coating gives a 3-6 times increase in the durability of the steel sheet.

Aluzinc reflects 75% of thermal radiation, and silicon additives increase the heat resistance of the alloy. The silicon content in this alloy increases the corrosion resistance and promotes particularly strong adhesion of the coating to the base, prevents the penetration of the oxidizing atmosphere into the metal, thereby creating a reliable protective barrier.

An important indicator of corrosion resistance is the time of destruction of the protective metal coating before rust on 5% of the surface when the test sample is placed in salt fog.

The rate of destruction of the protective coating in salt fog, respectively:

- Zinc - 10 hours/µm

- Galfan - 25 hours/µm

- Aluzinc - 100 hours/µm

(Low / High Carbon Wire, Ø1.50-8.00mm)

Zinc-Aluminum (Z-A) Coating Application Process

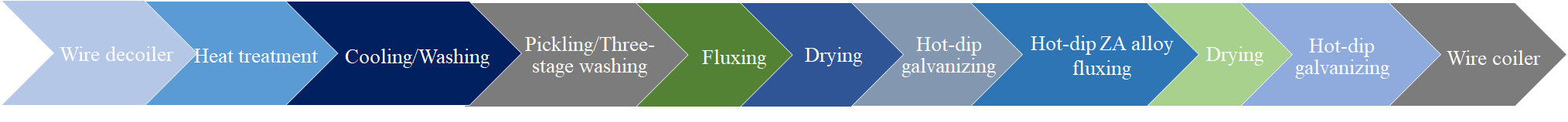

Low carbon steel wire (heat treatment + hot-dip Zinc-Aluminum alloy line)

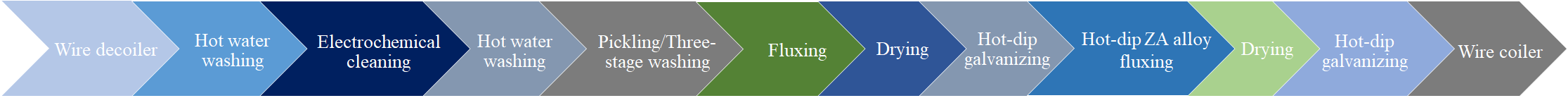

Low / high carbon steel wire (no heat treatment + hot-dip Zinc-Aluminum alloy line)

TECHNOLOGICAL EQUIPMENT DESCRIPTION AND PARAMETERS

| Wire material | C1006, C1008 |

|---|---|

| Wire diameter | ø 1.50-4.00 mm |

| Representative diameter | ø 2.89 mm |

| Production speed | 130 mm × m/min |

| Wire rod quantity | 14 rods |

Wire Decoiler

Decoiler: storage device with double coil (coil diameter: 500 mm), for 22 rods of wire.

Coil replacement is simple and easy to operate.

Decoiler devices are installed in a row, and the orientation of wire can be from right to left.

Heat Treatment Furnace for Wire

The main purposes of the heat treatment process for the wire are:

- improving the structure

- giving the metal strength

- giving the metal durability and other necessary properties

Heat treatment process usually includes the following steps:

- heating to a certain temperature

- maintaining that temperature for a certain amount of time

- cooling

Type of heating:

- natural gas (8500 × 4.18 kJ/m3)

- electricity four-wire three-phase 50Hz system

Annealing Furnace

Annealing furnace consists of the following components:

- 5 heating zones

- efficient burning system

- air supply system

- smoke removal system

There are several advantages of the Annealing Furnace:

- High heating efficiency

- Low maintenance

- Low gas consumption

- Low maintenance costs

The furnace is durable and has its own design, which allows to have a quick assembly and an easy further use. For isolation we use bricks which have strength grade 26 (ISOLITE JAPAN).

Surface Treatment Line

Parameters and Technical Requirements of the Production Line

| Wire material | 0.1-0.9% C |

|---|---|

| Wire diameter | ø 1.50 - 5.00 - 8.00 mm |

| Representative diameter | ø 3.2 mm |

| Production speed | 130 mm × m/min |

| Wire rod quantity | Total: 24 rods, two big lines in the middle, no-heat treatment |

| Nominal capacity | 3694,08 kg/h (ø 3,20mm) |

| Performance | 26597,37 t/year (7200 hours) |

Water and Air Cooling Bath

The bath is made of stainless steel SUS304, thickness 3 mm; bath length: 3 m; the frame is made of structural steel SUS304.

Wire washing – once; wiping – once; air blowing - once

Electrochemical Washing Bath

The bath is made of stainless steel SUS304; thickness 3 mm; bath length: 8 m; 4 leaching stages; type of electrolysis + - +, + - +, + - +, + - +

Wiping: once

Air blowing: once

Hot Water Washing Bath

The bath is made of stainless steel SUS304; thickness 3 mm; bath length: 8 m; the frame is made of structural steel SUS304.

Washing: once

Wiping: once

Air blowing: once

Pickling Bath

Bath length: 14 m

Pickling: 4 times

Three-stage washing bath

The bath is made of a copolymer of propylene and ethylene with a high content of polyethylene; bath length is 3 m. A circulation pump is used to spray and clean steel wire.

Hot-dip Z-A Coating Line Fluxing Bath

The bath is made of a copolymer of propylene and ethylene with a high content of polyethylene; bath length: 3.00 m

Fluxing: once

Hot-dip Z-A Coating Line Dryer

Made of steel plate Q235, thickness: 4 mm; frame made of structural steel Q235; length: 8 mm

Fluxing Bath

The bath is made of a copolymer of propylene and ethylene with a high content of polyethylene; bath length is 3 m.

Fluxing: once

Dryer

The dryer uses heated air to dry the wire. Made of steel plate type Q235; thickness 4 mm; frame made of structural steel Q235; length: 8.00 mm.

Hot-dip Galvanizing Furnace and Portal Frame

The galvanizing furnace is equipped with a zinc layer thickness monitoring system and a cooling system. There are 2 heating zones.

Zinc amount: 120 tons

Bath Material: Ceramics

The furnace and zinc temperature is controlled automatically; the ratio of gas and air is also adjusted automatically. Control sensors are located along the entire line.

The furnace is also equipped with a wax coating system. Water-soluble wax is used for wire coating to prevent corrosion and to lubricate the wire for further processes.

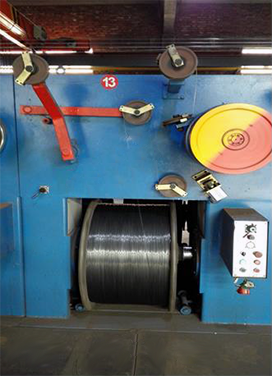

Wire Coiler

Wire coil specifications:

Internal diameter: 480 mm; outer diameter: 800 mm; wire coiler weight: 600 ~ 1000 kg

Wire coiler is equipped with a pneumatic tip for wire accumulation; trolley for wire transportation is placed on the ground; engine power – 0.55 kW