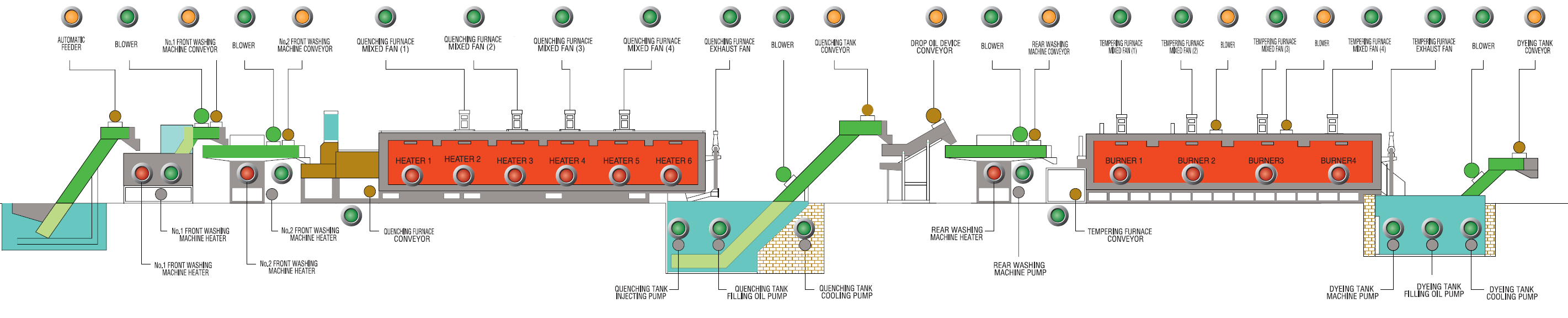

HEAT TREATMENT FURNACES FOR FASTENERS, METALWARE AND PARTS

GENERAL INFORMATION ABOUT THE HEAT TREATMENT EQUIPMENT

Integrated heat treatment of metals is the process of changing the structure of steel, non-ferrous metals, alloys on heating and subsequent cooling at a specific rate.

Thermal treatment (heat treatment) results in significant changes in properties of the steel, non-ferrous metal alloys.

The chemical composition of the metal is not altered. Furnaces for heat treatment of metals are intended for different types of heat treatment (hardening, annealing, tempering) of metal articles to a temperature of 1300°C.

There are many types of heat treatment furnaces, each designed for a specific process, has its technological advantages.

Fasteners, heat-treated in Taiwan Metiz Alliance furnace, delivered on such major car companies from around the world as FORD, CHRYSLER, HONDA, HYUNDAI, Mercedes-Bens, VOLVO, BMW, TOYOTA.

Also, a large number of special fasteners and parts used in engineering projects of the AERO Space company for different purposes.

Why do so many partners from around the world choose our equipment?

Taiwan Metiz Alliance conveyor furnaces have a modern design and have a number of features and key advantages over other conveyor furnaces on the market.

The 1st feature. The ability to heat treatment of fasteners and hardware components of different size, shape and purpose

Parts for cars, motorcycles, bicycles

Bolts, screws, nuts

Wire

Hand Tools

Details of hardware

Tooling for machine tools

Knives, stationery

Other parts

The 2nd feature. Fully automated control panel with all events indication

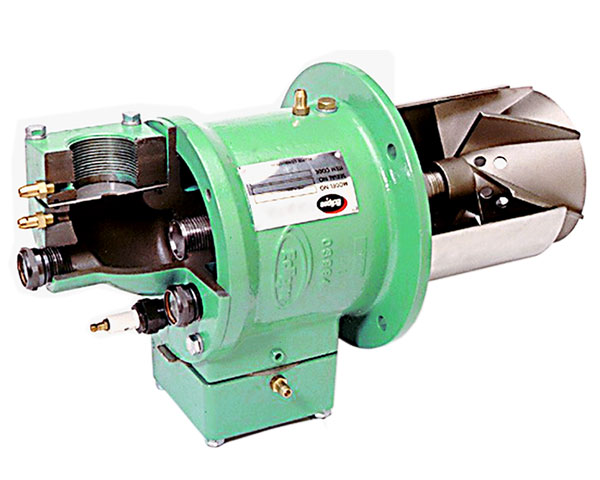

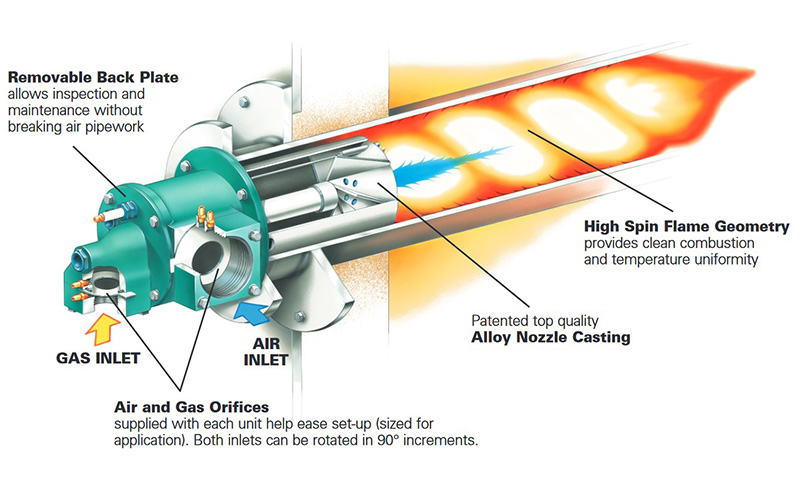

The 3rd feature. Know-how in gas burners system, furnaces for heat treatment, manufactured by ECLIPSE, USA

Features of the system of gas heating furnaces for heat treatment

The entire Eclipse system of gas heating was imported from the United States, including all safety devices. Eclipse Company offers its services in the market of heating systems for nearly 100 years, and is one of the largest manufacturers of gas heating in the world. The company has its official representative offices in India, Brazil, and other countries.

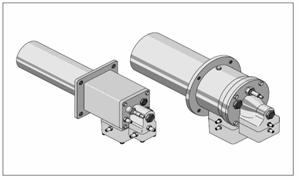

30 TFB gas burners system

In the hardening furnaces 30TFB burner system is used, thereby reducing fuel consumption by 20-27% smaller than with conventional gas burners.

Furthermore, the use of bayonet ultra recuperator improves quality and life of the burner.

Technology refers to the burners clean on the level of toxicity and does not harm the environment.

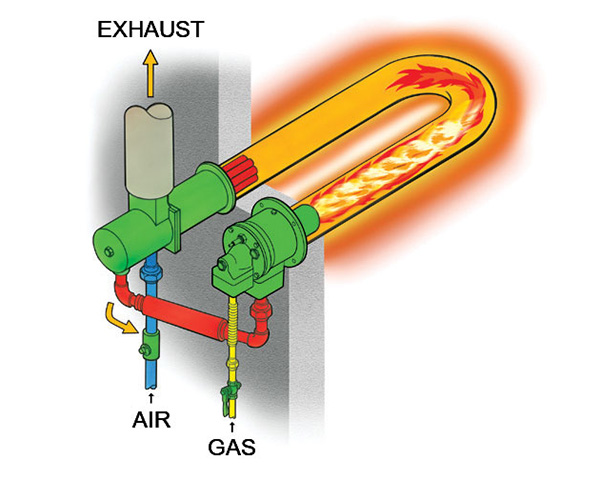

The 4th feature. Know-how in the design of the U-shape heating tubes

Know-how in the design of the U-shape heating tubes that was developed by Swiss engineers and have the GOST certificate.

U-shape tubes allows for uniform heating to within ±3°, made of cast mater of HU (SCH 20) brand, 6 mm thick, made in Switzerland. The service life of the tubes is about 5 years.

The 5th feature. High quality assurance of the line configuration from manufacturer

| Number | Title | Manufacturer | ISO 9001:2008 |

|---|---|---|---|

| 1 | Gas burner (model: TFB030) TJ0025MAT, | ECLIPSE | |

| 2 | Heat exchanger (4BU-24) | ECLIPSE | |

| 3 | Blower (SMJ-6619-5) | ECLIPSE | |

| 4 | Gas solenoid valve (P/:20170,120V, 1/2") | ECLIPSE | |

| 5 | Gas Regulator (P /N:10627,1/2") | ECLIPSE | |

| 6 | Regulator coefficient (ES366M,1") | ECLIPSE | |

| 7 | Regulator coefficient (ES366M,3/4") | ECLIPSE | |

| 8 | Hand throttle zone (108BVM,2") | ECLIPSE | |

| 9 | Automatic throttle zone (108BVM-A,2") | ECLIPSE | |

| 10 | Hand throttle zone (110BVM,21/2") | ECLIPSE | |

| 11 | Automatic throttle zone (110BVM-A,21/2") | ECLIPSE | |

| 12 | Air throttle zone (106BVM,111/2") | ECLIPSE | |

| 13 | Direct terminal Rajah (P/N:15996) | ECLIPSE | |

| 14 | Ignition transformer 6 kW (P/N:12178) | ECLIPSE | |

| 15 | Double valve to shut off the gas (DMV-D 702/6,p/n:20747) | DUNGS | |

| 16 | Managing the engine MODUTROL (M7284C1000,4-20MA) | HONEYWELL | |

| 17 | Protective relay against the flame (RA890G1260,120VAC) | HONEYWELL | |

| 18 | UV Scanner (C7027A1023) | HONEYWELL | |

| 19 | Air pressure switch (SMD) | ANTUNES | |

| 20 | Switch of low / high pressure gas (RHLGP-A) | ANTUNES | |

| 21 | Gas filter (GF80M-1-1616,2") | MAXITROL | |

| 22 | Pressure Regulator W (S208,2") | FISHER | |

| 23 | Heat exchanger (4BU-24) | ECLIPSE | |

| 24 | Pilot solenoid valve (p/n:20167, SIZE:1/4",120VAC) | ECLIPSE |