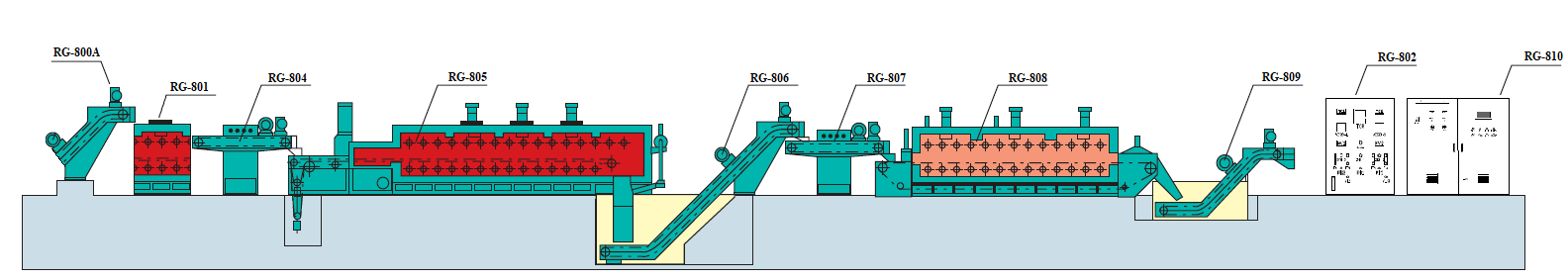

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

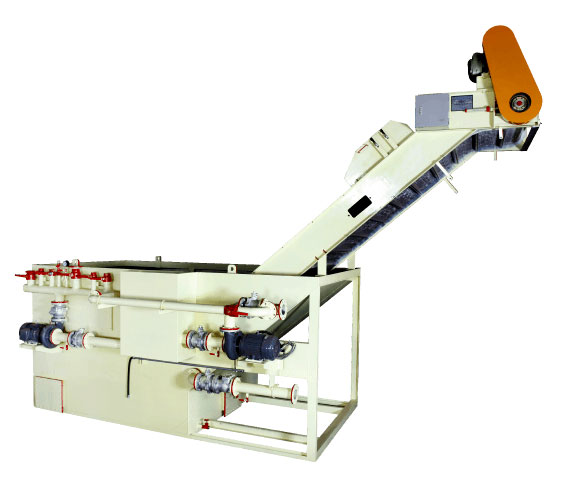

QUENCHING COOLING OIL / WATER TANK

Application & Features Quenching Cooling Tank RG-806

The products are proceeded the quenching process after heated by hardening furnace. The equipment uses a plate-type heat exchanger to control the temperature of oil rapidly. The tank is equipped with an injection cooling system; speed of injection can be adjusted freely according to the size of a work piece. A filter is installed in the tank, so the dirt is not stored in the heat exchanger; therefore, it prevents it from losing its cooling functions.

Technical Specification of Quenching Cooling Oil / Water Tank

| Model | Conveyor width, mm | Power (replacement), kW | Tank capacity, l | Cooling pump, hp | Pump for injection and circulation in tank, hp | External dimensions of the tank, mm | ||

|---|---|---|---|---|---|---|---|---|

| Width | Height | Length | ||||||

| RG-806-A | 800 | 10 | 8400 | 3 | 3 | 1530 | 2000 | 4200 |

| RG-806-1 | 800 | 10 | 8400 | 3 | 3 | 1530 | 2000 | 4200 |

| RG-806-2 | 1000 | 10 | 9400 | 3 | 5 | 1730 | 2000 | 4200 |

| RG-806-3 | 1000 | 10 | 9400 | 3 | 5 | 1730 | 2000 | 4200 |

| RG-806-4 | 1200 | 20 | 11600 | 5 | 7 ½ | 2100 | 2000 | 4200 |

| RG-806-5 | 1200 | 20 | 11600 | 10 | 10 | 2100 | 2000 | 4200 |

| RG-806-6 | 1200 | 20 | 11600 | 10 | 10 | 2100 | 2000 | 4200 |

| RG-806-6S | 1200 | 20 | 11600 | 10 | 10 | 2100 | 2000 | 4200 |

| RG-806-7 | 1400 | 30 | 12000 | 10 | 10 | 2200 | 2000 | 4200 |

| RG-806-7S | 1400 | 30 | 12000 | 10 | 10 | 2200 | 2000 | 4200 |

| RG-806-8 | 1600 | 30 | 12000 | 15 | 15 | 2300 | 2000 | 4200 |

Outlook of installed Quenching Cooling Tank

Technical characteristics of the Oil quenching bath

| Oil bath temperature | 60…80°С |

|---|---|

| Casing depth in hardening environment | 2300 mm |

| Unloading belt width | 1200 mm |

| Maximum capacity expended on heating, engines, pumps, blowers | 20,25 kW |

| The power consumed by motors | 1,5 kW |

| The amount of circulating cooling water | 78 m3/ h |

| Oil bath volume | about 13,000 liters (13 m3) |

| The residence time of products in bath | 4…20 min |

| Flat-type rollover mechanism – is a specific mechanism of patented design used for the collection of oil products and return them to the hardening bath. | |

Note: Electric heating system: for heating the heat received from the input of the hardening furnace casing is used, allowing heating oil up to 60 ... 80°C. In such cases additional heating is not required, so the sub-heaters are not necessary.

Schematic of the Oil quenching tank

Oil Quenching Tank RG-805-6 Components (for reference only)

| Pos. | Name | Note |

|---|---|---|

| 1 | Dimensions | W. 2,100 mm × H. 3,000mm × L. 4,200 mm |

| 2 | Width of mesh type conveyer belt | 1,200 mm |

| 3 | Quenching oil tank capacity (see *Note 1) | 11,600 liters |

| 4 | Automatic oil temperature control system | 1 unit |

| 5 | Heat exchanger:

| 1 unit |

| 6 | Oil Curtain pump 3HP (2.2 kW) (see *Note 2) | 1 set |

| 7 | Injection pump 10HP (7.5 kW) | 1 set |

| 8 | Conveyor

| |

| 9 | Conveyor belt

| |

| 10 | Conveyor chain

| |

| 11 | Floor level | |

| 12 | Blower: 5HP (3.75 kW) × 4P | 2 pcs |

Note 1: Above capacity is according with standard height of quenching tank by 3,000mm

Note 2: In tempering furnace casing there is an oil curtain created by spraying, that prevents oil vapors from the hardening bath through the casing in a tempering furnace; At the end of the tempering furnace there is an exhaust fan, which pulls and burns the oil smoke arising in the bath hardening in oil;