Equipment for additional treatment of fasteners, metalware and parts

AUTOMATIC CENTRIFUGE FOR LUBRICATION OF FASTENERS, METAL HARDWARE AND COMPONENT PARTS

Technical specifications and characteristics of the equipment

- The line (optional): 5 cycles × 500 kg × 8 hours × 25 days × 0.9 = 450 tons / month

- Capacity: 380 V, 50 Hz

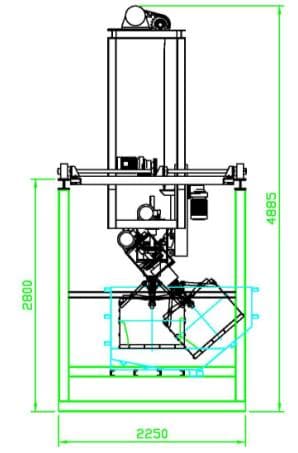

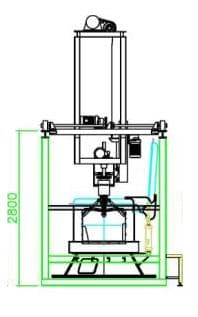

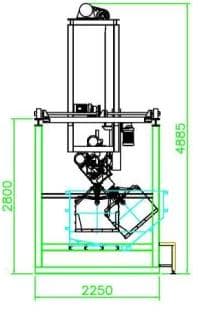

- Installation of the clamping type crane, 1 set. The function of the crane: capture and movement of the basket.

- Installation is controlled by a computer managing system with frequency converter

- The time of one cycle of production is 12 minutes

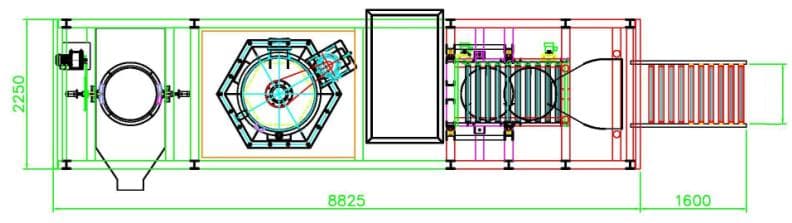

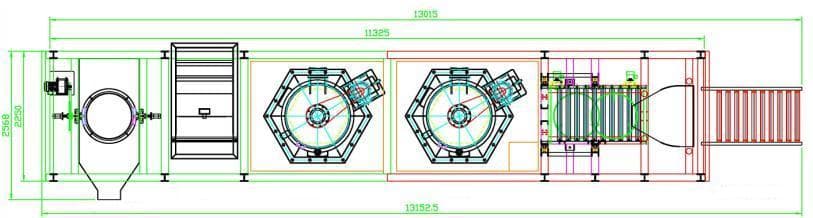

- The equipment line consists of 4 components: a feeding unit, parts oiling unit, centrifuging unit and unloading unit.

- Equipment Dimensions (L×W×H): 8825×2250×4885 mm

Additionally equipped with roller type loading conveyor of 1600 mm length, width of the conveyor is determined by the customer's request.

- Loading unit (feeding conveyor)

- Parts oiling unit

- Centrifuging unit

- Unloading unit

PRODUCTION

The production process is fully automated and controlled by PLC of Japanese production, Mitsubishi.

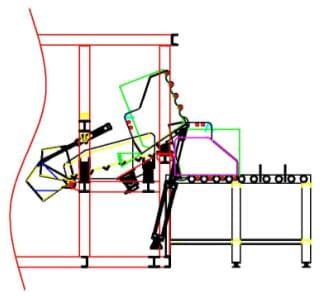

Technology of production is as follows:

- Parts unloading to basket.

- Grab a basket by crane.

- Immersion to oil.

- Centrifugation.

- Roll-over unloading of finished products.

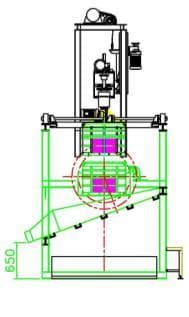

The advantage of such lines is that it is possible to design any number of centrifuges and dipping into the oil bath (depending on performance), the setting time dipping, the treatment time in the centrifuge is given on the operator panel. Available automatic control by PLC (programmable logic controller) and manual.

Completed projects of equipment for oiling hardware, fasteners and parts

AUTOMATIC CENTRIFUGE FOR DEGREASING FASTENERS, METAL HARDWARE AND COMPONENT PARTS

- Loading unit (feeding conveyor).

- Centrifuging unit.

- Parts degreasing unit.

- Unloading unit.

TECHNICAL SPECIFICATIONS AND FEATURES OF THE EQUIPMENT

Technical specifications and characteristics of the equipment

- The line (optional): 5 cycles × 500 kg × 8 hours × 25 days × 0.9 = 450 tons / month

- Capacity: 380 V, 50 Hz

- Rollover mechanism of loading tank engine 3 hp

- Vibration motor of 0.5 HP

- Conveyor engine 0.25 hp

- centrifuge 15 hp

- Unloading stand engine 0.25 hp

- Total capacity of 35.35 hp, effective power of 70%

- Installation of the clamping type crane, 1 set. The function of the crane: capture and movement of the basket.

- Installation is controlled by a computer managing system with frequency converter

- The time of one cycle of production is 12 minutes

- The equipment line consists of 4 components: a feeding unit, parts oiling unit, centrifuging unit and unloading unit.

- Equipment Dimensions (L×W×H): 11325×25680×4885 mm

Additionally equipped with roller type loading conveyor of 1600 mm length, width of the conveyor is determined by the customer's request.